Imagine this, you open up your food to eat, perhaps its a nice ham sandwich, perhaps a slow cooked lamb slathered in gravy and succulent juice. Just as you begin to eat it, your cheeks swell up, you begin to feel faint and everything goes black. Let’s rewind 2 weeks, to when the product was being prepared. Now what happened here, freak accident? Listeria outbreak? No, it was a simple peanut cross-contamination. But how can this be prevented? Introducing FMCG’s newest product, the AgraStrip!

As supply chains and food processes become more complex and varied, it becomes increasingly more important to utilize detection methods. How can you be sure that the product you’re putting out is 100% free from allergens? Well, it’s extremely difficult to investigate the sourcing of every ingredient and item used in the production process. Rather, robust testing procedures at every stage of the production process must be implemented.

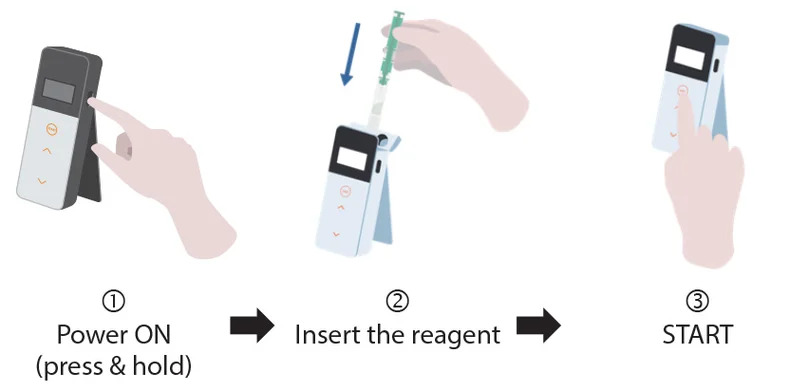

So, what is the easy solution? Well, FMCG provides an easy allergen test kit called the AgraStrip. The Agrastrip is a device which tests for peanut residue in raw materials, finished food products, beverages, rinse waters and environmental samples. Moreover, detection is quick and painless for the user. Testing for peanut residue accurately and efficiently is incredibly vital, as consequences of inadequate or inaccurate tests can vary from mild fever or illness, to life threatening problems for people with extremely severe peanut allergies. Additionally, failing to follow the relevant laws surrounding the food industry can lead to harsh penalties.

Click here to learn more about the Agrastrip Allergen test kit and click here to read more about the importance of allergen management in the food industry.

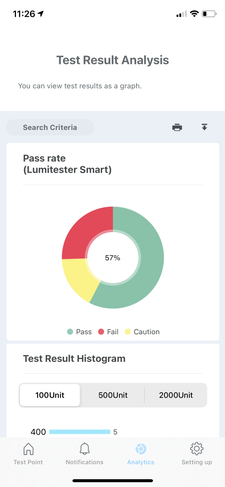

Exportable Data and Reports for Regulatory Compliance

Exportable Data and Reports for Regulatory Compliance

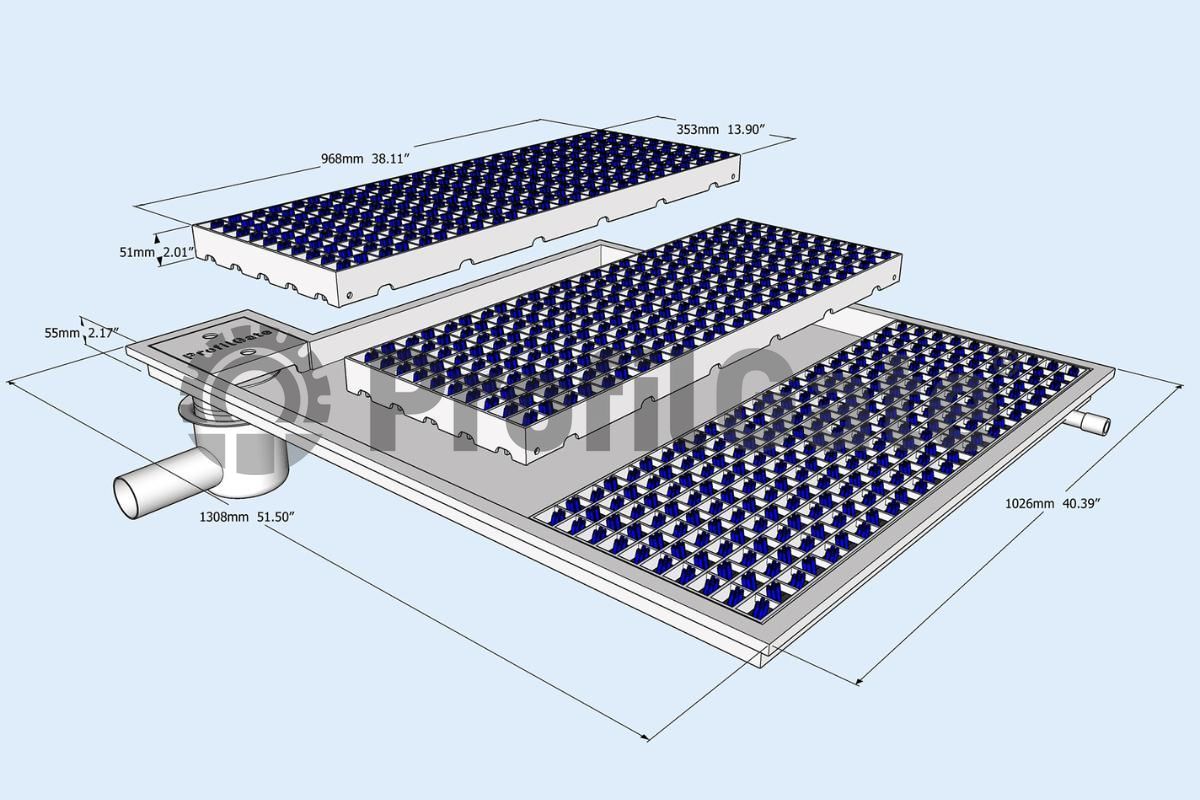

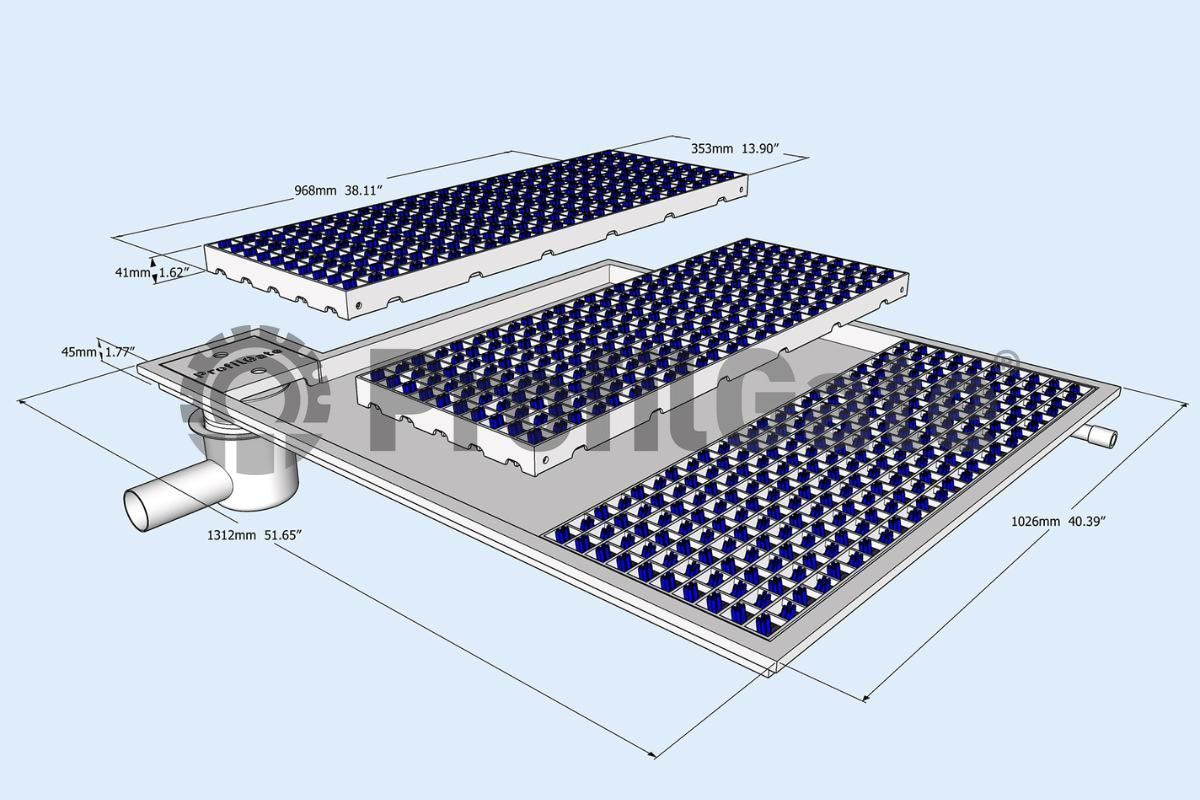

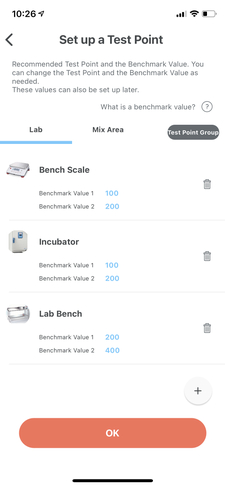

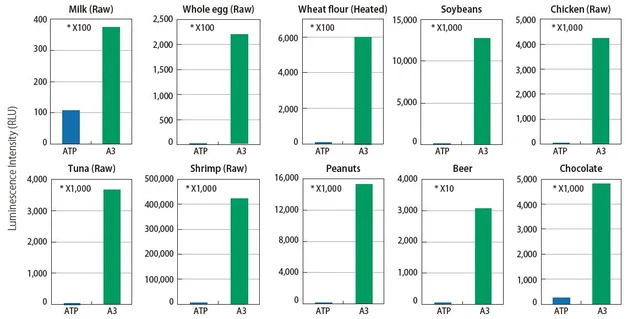

See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t